CiA® 434: CANopen profiles for laboratory automation systems

The CiA 434 set of device profiles specifies the communication between a laboratory automation controller (LAC) and several laboratory automation units (LAUs). In addition to the general definitions (CiA 434-1), device profiles are provided for dilutors, dispensers, and pump units (CiA 434-2), as well as for heating, cooling, and shaking units (CiA 434-3). The scalable LAU device modeling is applicable for both small and simple applications as well as for very complex ones. Thus, the device manufacturer can provide the same electronic CANopen interface implementation for diverse laboratory equipment and simply adapt the required application functionality.

The specified finite state automaton (FSA) defines the behavior of the LAU as seen by the LAC. FSA state transitions are based on internal device events (e.g., occurrence of device errors, local inputs) or on the reception of FSA commands from the LAC. The error-free device may be in the idle state, configuration state, interrupted state, or command processor active state. In the latter, either directly received or batched commands are executed. In direct execution mode, the LAC sends single operation commands to the LAU. The LAU starts executing the command immediately after receiving the entire command and generates the command result. In batch mode, received operation commands are stored in command buffers. This allows the LAC to pre-program work plans within the LAU.

Two classes of operation commands are defined: process commands and system commands. Process commands directly trigger specific LAU behaviors, such as dosing a certain volume or shaking at a given frequency. System commands influence the type of command processing and are mainly used in batch mode. The general LAU control objects include the control word, the status word, the operation command result, and the system command parameter record (e.g., for loops). Additionally, specific objects for batch mode and direct execution mode are specified. The profile allows for the transmission of command structures via PDOs (process data objects) in a segmented manner, although this is not recommended.

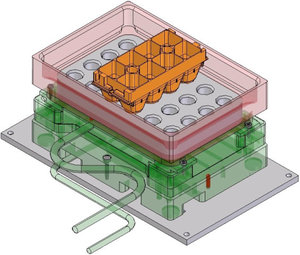

CiA 434-2 specifies commands and parameters relevant for controlling dilutors, dispensers, and pump units. A dilutor aspirates a specified liquid volume into a syringe in the first step and dispenses this liquid in the second step. Among other functions (e.g., dispensing, serial dispensing, diluting, or generating a continuous flow), a dilutor unit may control drives (e.g., DC motors, stepper motors), various types of valves, or different types of syringes. A dosing pump relies on a variable-capacity vessel, such as a syringe, to aspirate and deliver precisely controlled volumes of liquids. The specified process commands distinguish between general commands and function-block-specific commands, such as those for dosing, valves, flow tables, and pressure tables. Additionally, it specifies how the supported function blocks are represented and how field values given in increments are converted to SI-unit-related process values. The values with appropriate SI units (coded as specified in CiA 890, formerly CiA 303-2) for current flow, accumulated volume, and current pressure, along with the remaining processing time, are detailed. At the end of this specification part, the detailed parameter sets for each function block are specified.

CiA 434-3 specifies the heating, cooling, or shaking (HCS) unit. The general commands include the total initialization and software initialization commands, the stop process command, and the move lifter command. The parameter sets for the temperature function block provide the standby temperature, heating and cooling ramps, two target temperatures, and temperature cycles with additional ramps. The parameter sets for the shaking function block include the shaking frequency, acceleration and deceleration ramps, two target shaking frequencies, and shaking cycles with additional ramps.

Profile-compliant CANopen CC devices support a bit rate of 500 kbit/s (and optionally others) and one of the two specified connectors (see also CiA 106). The CANopen NMT (network management) manager functionality is implemented in the laboratory automation manager, while the other devices provide CANopen NMT server functionality. Emergency messages and heartbeat functionality (see CiA 301) are also supported.

| Title | Details | Published Size |

Status Action |

|---|---|---|---|

|

|

ScopeThis document recommends the connector pin-assignment for CAN interfaces. This includes the CAN_H and CAN_L pins, the ground pin, and the power supply pins. |

2023-07-11 896 KB | TR Login |

|

|

ScopeThis specification specifies the CANopen application layer. This includes the data types, encoding rules and object dictionary objects as well as the CANopen communication services and protocols. In addition, this specification specifies the CANopen network management services and protocols. This specification specifies the CANopen communication profile, e.g. the physical layer, the pre- defined communication object identifier connection set, and the content of the Emergency, Time- stamp, and Sync communication objects. |

2011-02-21 3 MB | PAS Login |

|

|

ScopeThis set of device profiles for laboratory automation systems describes a master/slave-based communication between a laboratory automation master and several laboratory automation slaves (units). In addition to the general system structure, this part of CiA 434 defines a finite state machine (FSA) that is supported by all laboratory units, following the specification CiA 434. In addition, this part specifies two predefined control structures for laboratory units. On the one hand, the laboratory automation master can control the laboratory units via single operating commands. On the other hand this part provides a generic structure for a “pre - configurable work plan” that enables a quasi -autonomous laboratory unit operation, which is monitored by the laboratory master. The set of CANopen profiles for laboratory automation systems includes several parts: Part 1 describes general definitions; Part 2 defines the device profile for dilutor/dispenser/pump units; Part 3 defines the heating, cooling and shaking unit; Part 4 defines the device profile for pipette control units; Part 5 defines the device profile for multi axis control units; Part 6 defines the device profile for drive units; Part 7 defines the device profile for washing units; Part 8 defines the device profile for centrifuge units; Part 9 defines the device profile for stacker units; Part 10 defines the device profile for detection units. Devices compliant to these profiles use communication techniques, which conform to those defined in the CANopen application layer and communication profile (CiA 30 1). In addition, they may use communication techniques, which conform to those described in the set of specifications for additional application layer functions (CiA 302). These specifications should be consulted in parallel to these device profile specifications. |

2009-04-22 1 MB | DSP Login |

|

|

ScopeThis part of the CANopen profiles for laboratory automation systems defines the CANopen interface for dilutor, dispenser and pump units. Based on the definitions given in CiA 434 -1, this CANopen device profile specifies commands as well as parameters relevant for controlling dilutor, dispenser and pump units that are part of an automated laboratory system. |

2010-06-30 1 MB | DSP Login |

|

|

ScopeThis part of the CANopen device profiles for laboratory automation systems specifies the heating, cooling and shaking unit. |

2010-06-30 531 KB | DSP Login |

|

|

ScopeThis document provides recommendation how to represent the international system of units and prefixes in parameter specifications. It recommends also the structure of configuration parameters for SI units and prefixes. |

2023-01-10 267 KB | TR Login |